The History and Workings of Whitchurch Silk Mill – talk by Deborah Wheeler

Deborah Wheeler from the Whitchurch Silk Mill spoke to members at our February meeting. She displayed a number of samples of the mill’s woven silk materials together with silk cocoons, silk waste, silk cones and silk on a shuttles.

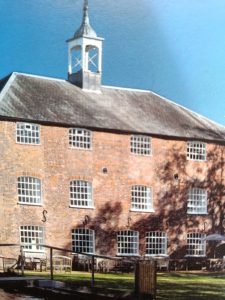

The mill has a long history going back to 1813 when it was built on land owned by the Dean and Chapter of Winchester, by business man Henry Hayter and his son William. Another floor was added by the next owner, silk merchant William Maddick. Local families named Chappell and Hide have also owned the mill and in 1956 silk manufacturers Stephen Walters and Sons stepped in to buy the mill to ensure production continued. Ede & Ravenscroft, makers of academic and legal gowns, bought the mill but by the mid 1980’s the mill had fallen into disrepair. It was rescued by Hampshire Buildings Preservation Trust and in 1990 the mill was opened under the management of the Whitchurch Silk Mill Trust.

The mill is situated on the River Test, a chalk stream and has 6 sluice gates which control the water wheel. Today Whitchurch Silk Mill is open to the public six days a week thanks to 12 staff and a group of 70 volunteers. The silk mill produces silk for the public, for film sets, the theatre, television, the National Trust and the Historic Houses Association. Thanks to a Heritage Lottery fund grant the mill now has a looms to make scarves and stoles..

We were shown the life cycle of the silk worm and some silk cocoons. It was explained how the silk is spun, how the warp threads are set up on the loom and how the shuttle weaves the weft at speeds of about 30 mph. Until recently silk hanks were bought direct from China but now cones are bought through Stephen Walters. I found it interesting to see the sample cards of between 150 to 200 threads per inch which are used to create new designs. The chosen design is then recorded in the weaver’s diary. It was very encouraging to hear that the skill of spinning and weaving silk has been passed on to the next generation but alarming that there are only 5 such people in the country with 3 working at the Whitchurch Silk Mill.

We all agreed this would make a wonderful day out in the summer especially as the mill has its own restaurant so hopefully we would be able to see one of the talented people at work making silk and silk ribbon.

Report and photos by Ros

Whitchurch Silk Mill Website giving details of opening hours, location and their shop: https://whitchurchsilkmill.org.uk/

Silk thread, hand dyed cocoons etc: https://www.21stcenturyyarns.com/

Silk thread, hand dyed cocoons and silk waste: https://www.stef-francis.co.uk/